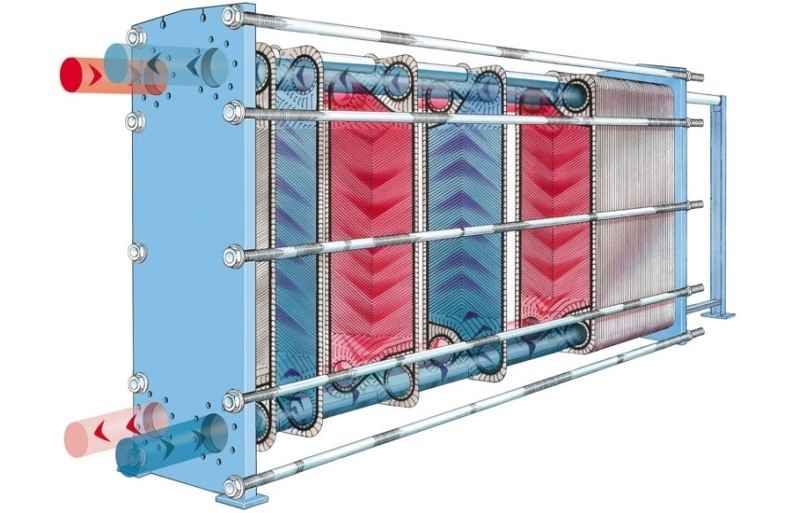

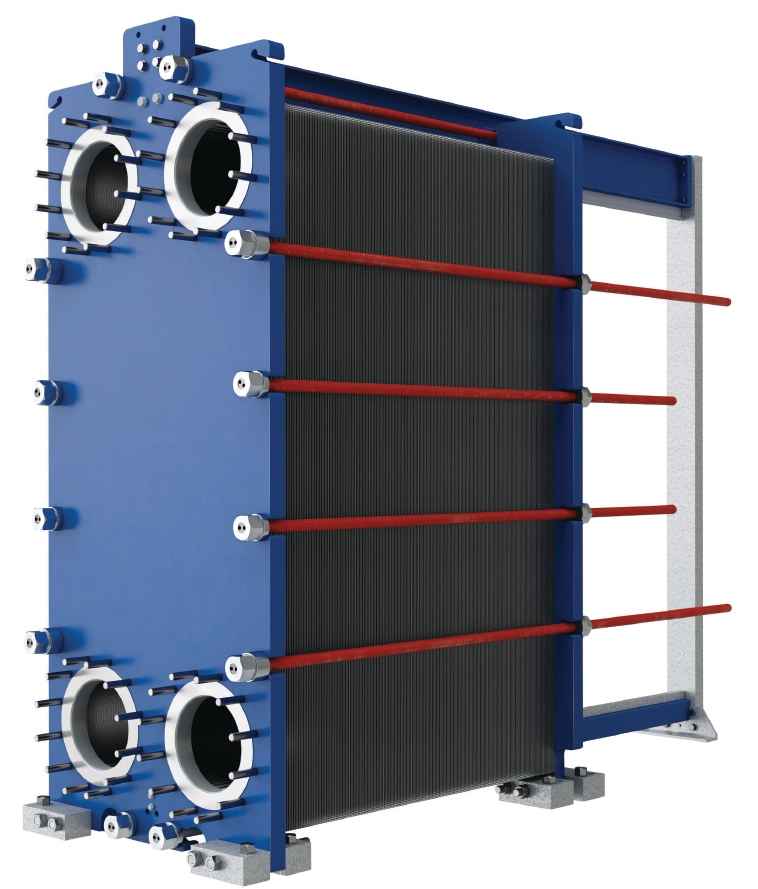

Plate heat exchanger is a type of heat exchanger that consists of a large number of corrugated sheets made of stainless steel, titanium, nickel and etc. These plates are separated by polymer washers and placed inside a steel frame. The main components of a plate heat exchanger include frames, plates and washers. The plates that make up the heat exchange surface are fastened by bolts between two plates or steel. The structure of these heat exchangers is such that it is possible to open the plates for inspection and cleaning them. Each plate has a washer whose job is to seal the plate and under the pressure of the fluid transfer network in the plate pack.

Proper design allows a set of plates to be held together by screws. The washers prevent leakage out and direct the fluids in the plates as desired. Fluids flow is generally chosen so that the flow of fluids is in opposite directions. Gasketed Plate Heat Exchangers are usually limited to fluid flow with a pressure below 25 bar and a temperature below 170 °C.

Strong eddy current causes large heat transfer coefficients and pressure drops. In addition, high local shear stress reduces fouling. Gasketed Plate Heat Exchanger provides a relatively compact, lightweight heat transfer surface. Their temperature and pressure are limited due to their structure details. These types of heat exchangers are easy to clean and sterilize because they can be completely dis-assembled from each other and are therefore widely used in the food industry.